- Home | Industry Update | Textile Concrete Emerges As Smart Solution For Stronger, Lig...

Textile Concrete Emerges as Smart Solution for Stronger, Lighter, Greener Structures

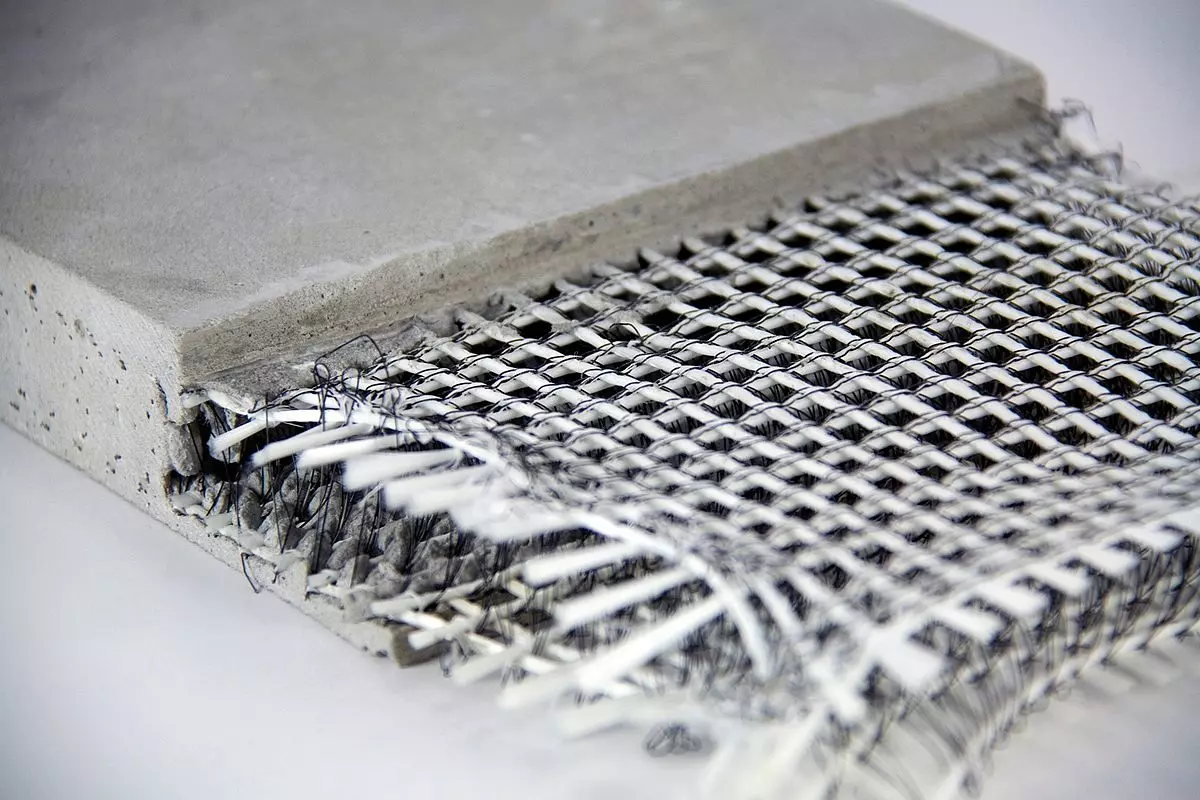

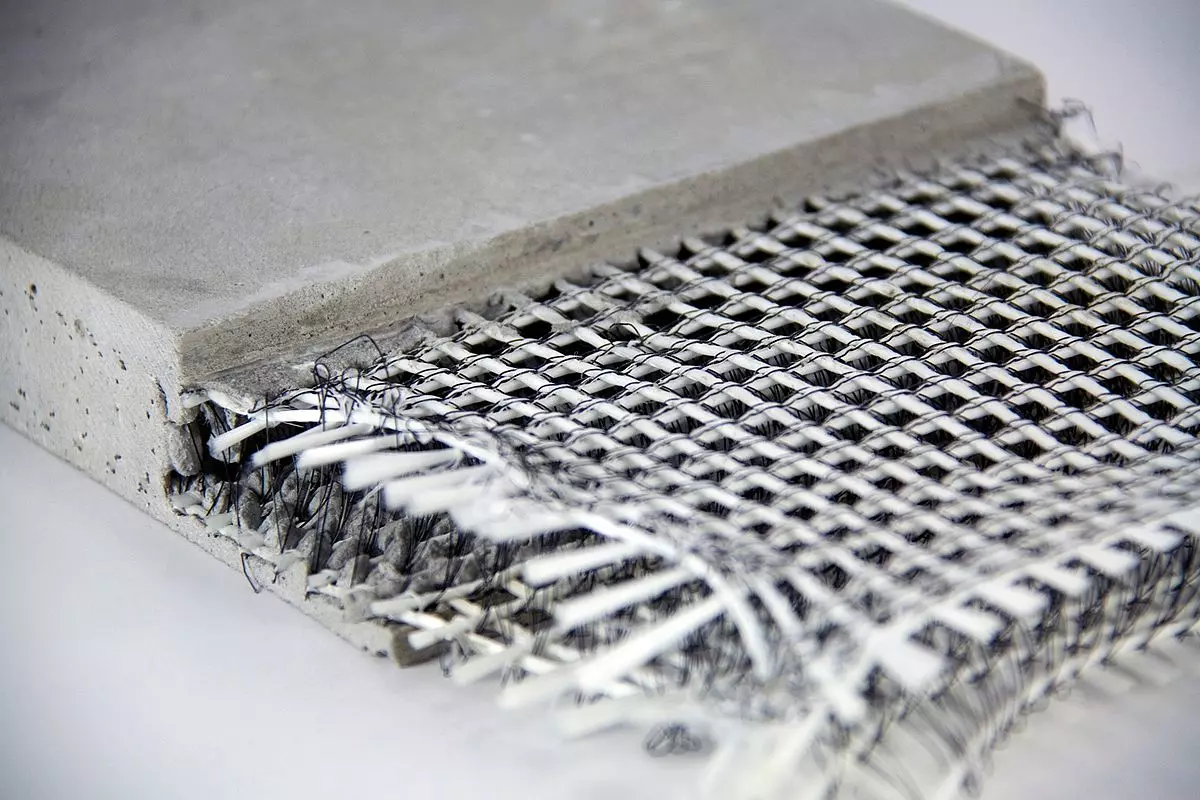

Revolutionising the construction landscape, a new wave of research is breathing life into concrete with the help of textile fibres. As the industry moves toward lighter, more efficient, and sustainable building materials, textile-reinforced concrete (TRC) is steadily gaining attention for its remarkable structural benefits and long-term economic value.

Unlike traditional steel-reinforced concrete, TRC uses fibre mesh to replace metal bars, eliminating the need for bulky concrete covers. This results in slender structural members that do not compromise strength. These textile-based composites enhance ductility, reduce cracking, and allow for more compact, cost-effective designs transforming the way structures are conceived and built.

TRC is not only effective in creating new architectural elements but is also proving highly beneficial in retrofitting and strengthening old constructions. With high fire resistance, flexibility, and reduced corrosion risk due to its nonmetallic composition, TRC offers a promising alternative to fibre-reinforced polymers that have long dominated the repair segment.

Globally, scientists are rigorously testing various fibre types, mix designs, and tensile properties to understand and model TRC’s behaviour. While many trials focus on tensile and flexural strength, efforts are also underway to develop precise bond-slip models that reflect how embedded fibres interact within concrete.

A comprehensive science mapping approach now brings clarity to the field. Through bibliometric insights and qualitative analysis, researchers have outlined key performance indicators and future directions paving the path for textile concrete to become a central pillar in sustainable architecture and resilient urban infrastructure.

03:23 PM, Jun 26

Source : Textile Concrete Emerges as Smart Solution for Stronger, Lighter, Greener Structures

.webp)

.webp)

.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

.png)

.jpg)

1.jpeg)